Considering investing in fill and seal machinery for premade pouches? The market for flexible packaging is experiencing rising interest in premade pouches, particularly in the food and beverage sectors. This demand is being driven by convenience and portability concerns.

How do you choose which premade pouch filling and sealing equipment manufacturer is most suited to your needs? And, when you have decided, what types of premade pouch filling machines are available?

Here is a quick guide to premade pouch filling machines to help you make an informed decision about the packaging machinery for your business.

Automatic Pouch Filling Machine Design Considerations

Premade pouch filling machine is available from a number of different vendors that specialize in packaging equipment. This is fantastic since more competition leads to increased innovation and better prices for the consumer in the end.

When looking for premade pouch packing equipment, you may find yourself confronted with a large number of available possibilities. In these situations, it may be difficult to choose which aspects of these machines to prioritize when doing an assessment.

In order to make the process of selecting equipment to fill and seal premade pouches more manageable, we have compiled a few quick pointers, which are as follows:

1. Find out whether the equipment is powered by mechanical or servo mechanisms

Standard mechanical drives are capable of doing the task satisfactorily, but they do have some drawbacks.

Servo drives provide for a more accurate and smoother operation because of the position input they offer. Additionally, servo drives may provide increased packing speeds.

Because of these reasons, servo-driven machines are a better investment in the long term, even though they may cost more initially.

2. Pay attention to the pre-designed machine setup for making pouches

Is it easy to get to and open, allowing for fast, simple changes as well as efficient cleaning and maintenance?

Is it possible to alter the settings with little effort and without having to move about the electrical cabinets or the HMI?

Regarding the human machine interface (HMI), is it positioned in a fixed position or does it have a suitable location on a swing arm that allows for maximum flexibility?

The thing that we’re trying to get over here is the need of keeping the machine unfettered and accessible so that it can accommodate both accessibility and flexibility. The people who operate the machines and maintain them will be grateful to you. Also, this will make it easier to introduce new products.

3. Is the machine able to handle heavier fills?

A good pouch filling machine for premade pouches would include pouch grabbing arms made of stainless steel that can hold at least 10 kg between them.

Consequently, this prevents the gripper arms from drooping over time while holding larger and bulkier product loads.

Even if you do not now need big product fills, having the potential to do so in the future is a nice alternative to have in your pocket even if you do not.

The gear you choose for flexible packaging should have the capacity to expand as your business does. Plus, the fact that you could do this without having to replace the whole packaging line is an important consideration.

4. Determine your speed requirements

How fast do you want the premade pouches to be filled and sealed?

The pouch filling machine that you choose should have a top speed that is 1.5 to 2 times greater than the fastest speed you will require.

The primary reason for this is that as the pouch filling machine begins to age, its performance will degrade gradually.

Purchasing a machine with a top speed that is much greater than you need gives you some wiggle room so that your production line doesn’t have to come to a screeching halt due to a slow-down in the pouch filling process.

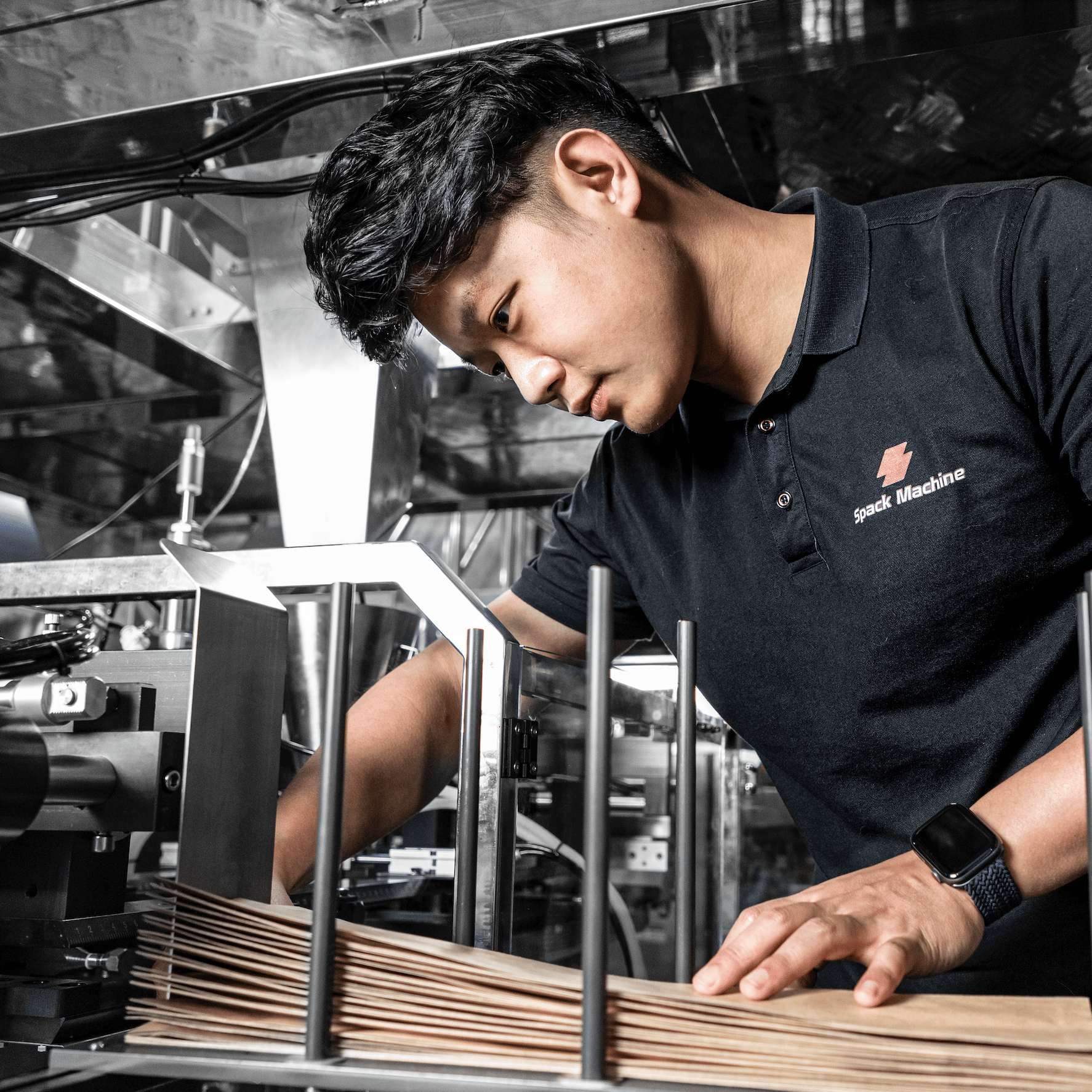

5. Request a demonstration of the pre-made pouch filling machine

It is important to see how premade pouch filling machine works in person because it will give you a much better understanding of how it can be integrated into your packaging line.

The best approach to judge the packing equipment is to use it and ask the people who use it every day what they think.

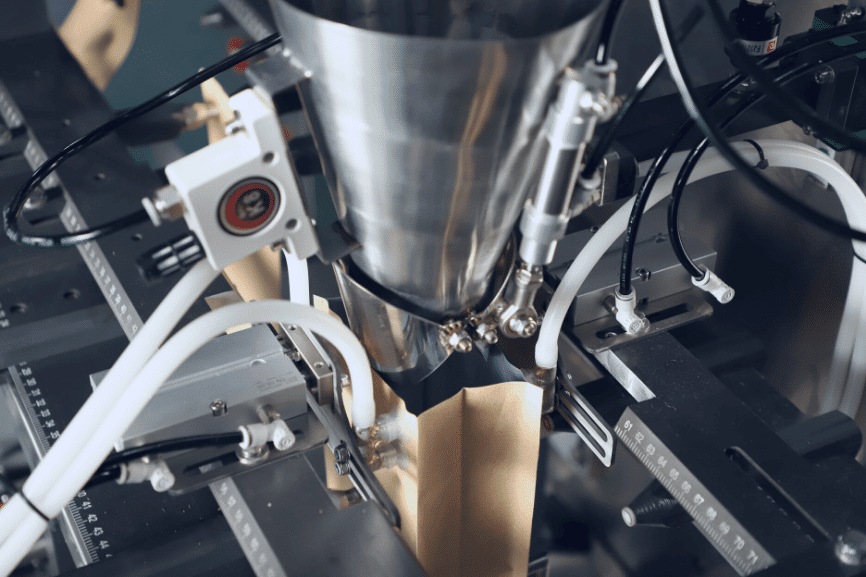

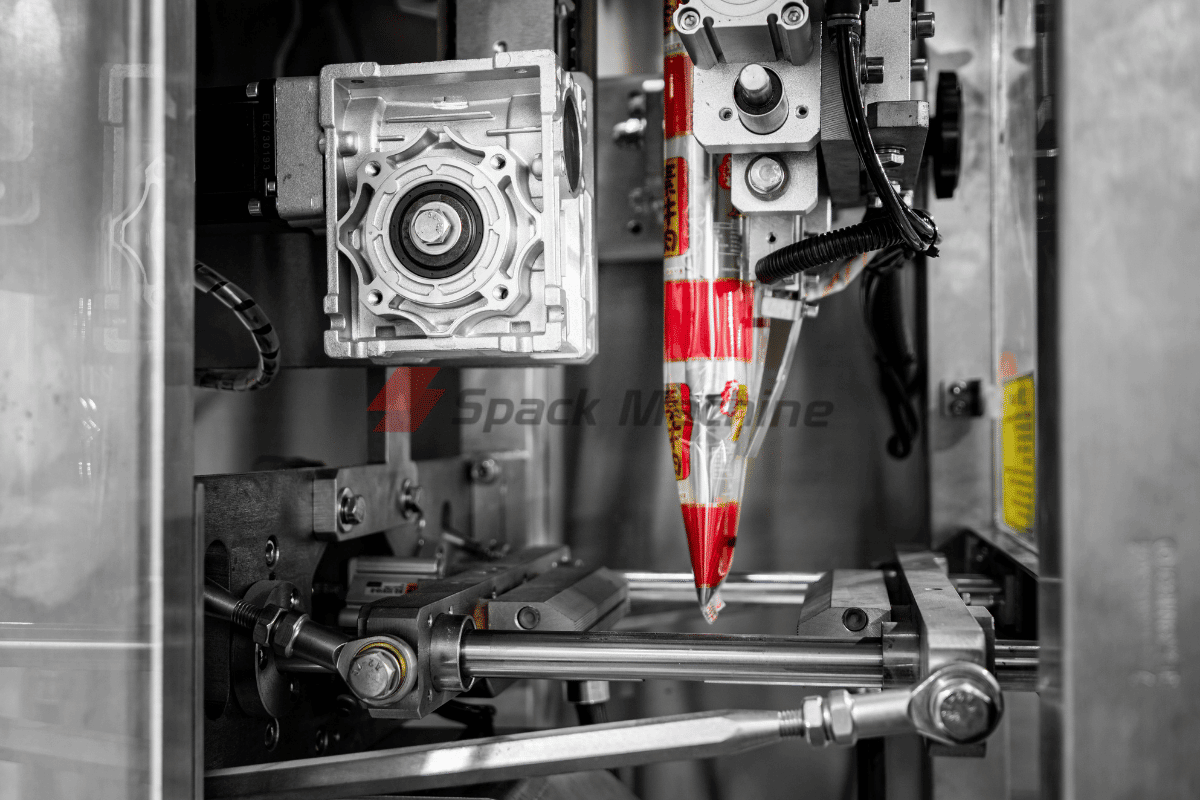

Additionally, ask the vendor to show you how easy it is to change over the premade pouch filling machine from one type of premade pouch to another.

This is an important consideration because you want to make sure that the pouch filling machine you choose can be quickly and easily changed over so that it is able to accommodate the different types of premade pouches that you use.

The premade pouch filling machine is a vital part of any packaging line. It is important to choose the right one for your needs so that your packaging line runs smoothly and efficiently.

6. Pay attention to how noisy the equipment is while running

In most cases, higher worn components are associated with packing equipment that produces a louder noise.

The longer a system is down for repairs and the more money is spent on replacement components, the higher the TCO becomes.

If you’re looking for a premade pouch filling machine with a low TCO, look for one that doesn’t produce too much noise while in operation. You can consult with the vendor to get an idea of how much noise the premade pouch filling machine makes while it is running.

7. Consider your power consumption needs

The premade pouch filling machine you choose should be energy-efficient.

Look for a machine that doesn’t consume too much power while in operation. This will help to keep your operating costs down.

Ownership Cost vs. Initial Investment

There’s no getting around the fact that purchasing high-quality premade pouch packaging machines call for a considerable outlay of cash.

Consider the entire value as well as the total cost of ownership of the equipment rather than just looking at the numbers and selecting the packing equipment manufacturer that gives the lowest pricing.

There is always a justification for a difference in price between two manufacturers of packing equipment, even if one offers their (apparently identical) equipment for half the price of the other.

There is a possibility that purchasing packaging equipment that initially saves you $50,000 might wind up costing you twice or even three times as much if you include in the cost of maintenance, replacements, re-configuration, and productivity loss caused by the machine being down.

Simply put, it is important to factor in all the costs associated with premade pouch filling machines before making a decision.

A lower initial investment might be more attractive, but it could end up costing you more in the long run.

Don’t be afraid to ask challenging questions to pack machine manufacturers

You should feel confident in asking the premade pouch filling machine manufacturers any questions that you have. After all, you are looking to make a significant investment and you want to be sure that you are getting the best possible value for your money.

Some challenging questions that you might want to ask premade pouch filling machine manufacturers include:

- What is the expected lifespan of the premade pouch filling machine?

- What is the average downtime of the premade pouch filling machine?

- How easy is it to change over the premade pouch filling machine from one type of premade pouch to another?

Takeaways

When purchasing a premade pouch filling machine, it is important to consider all of the associated costs in order to make an informed decision. By asking the right questions, you can be sure that you are getting the best possible value for your money.

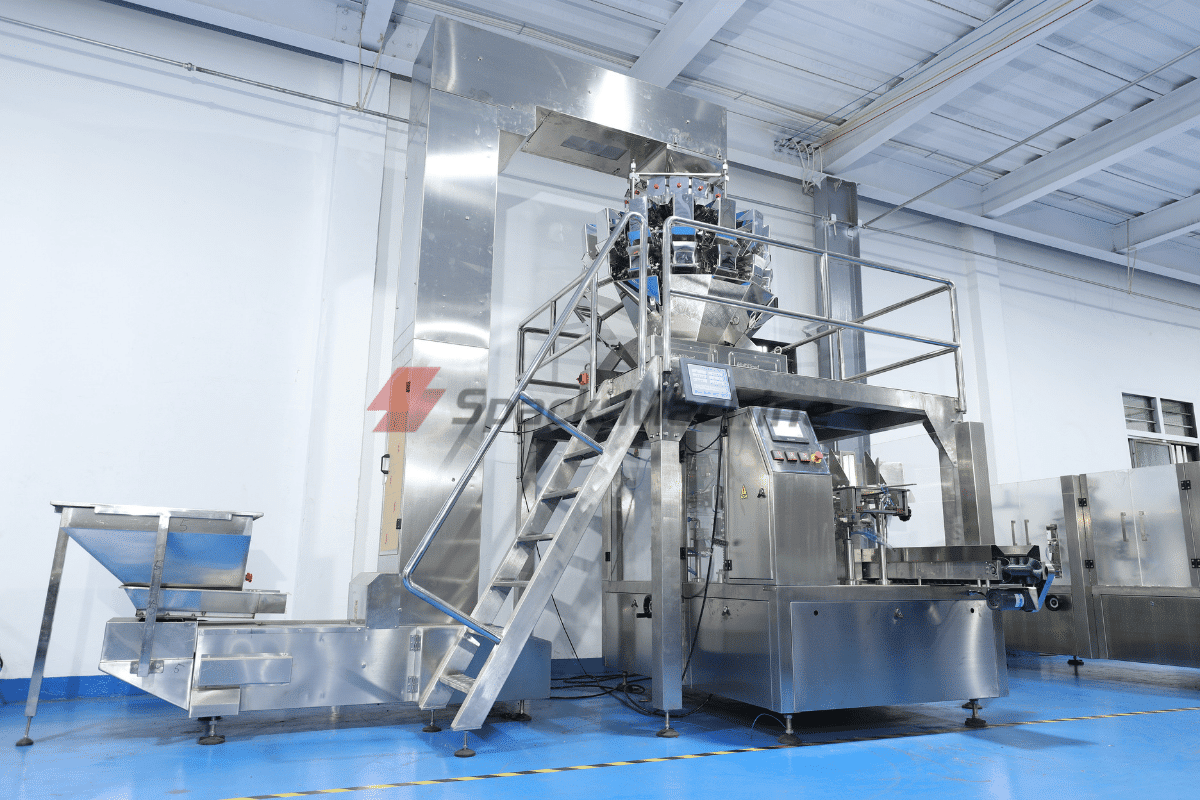

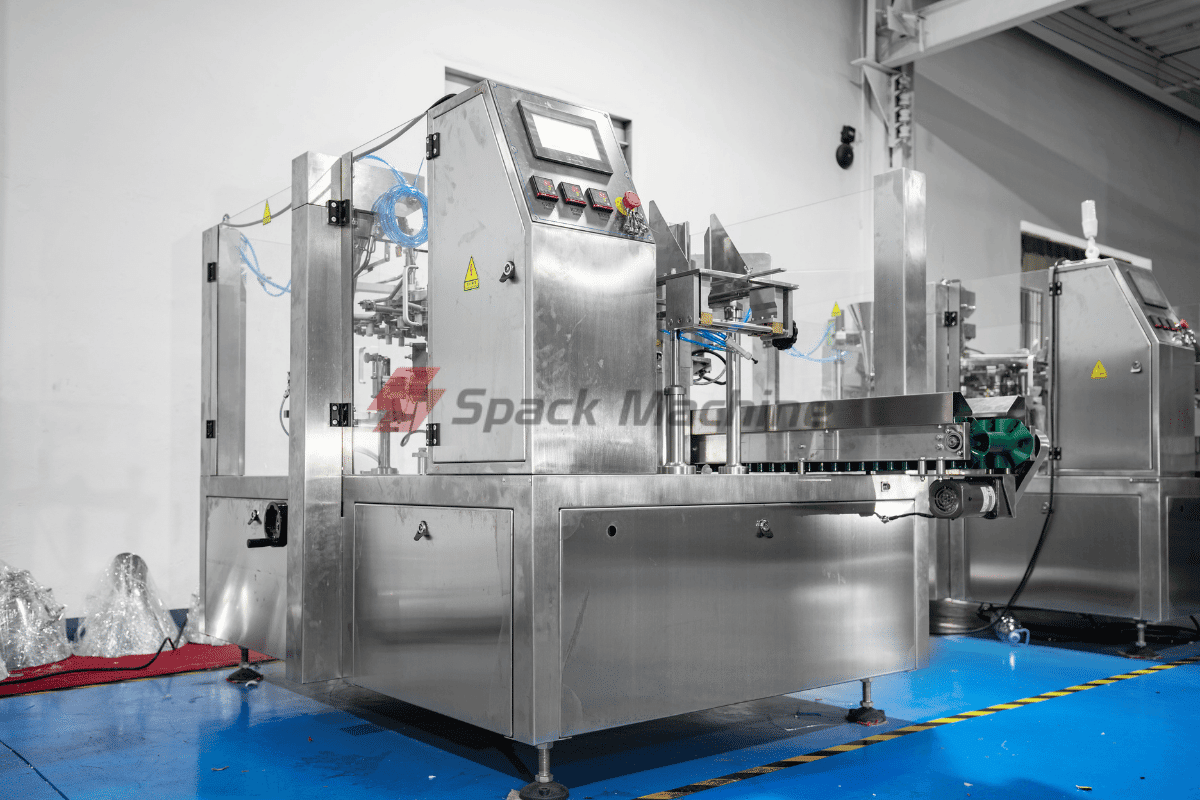

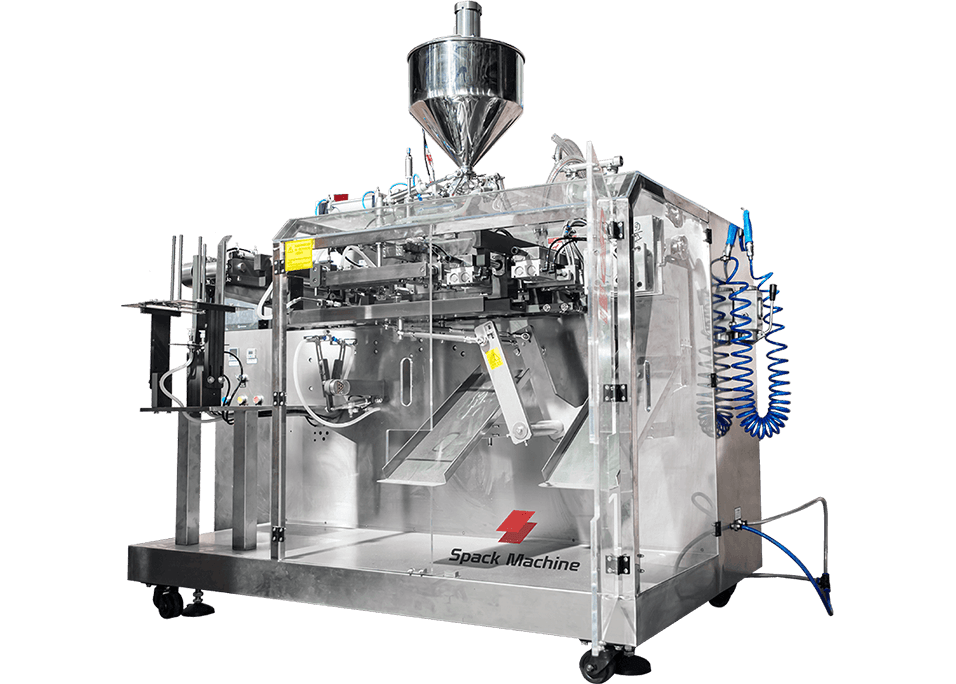

Should you need professional help, Spack Machine is always here for you! We offer a wide range of premade pouch filling machines that are sure to meet your needs. Contact us today to learn more!

0 Comments